Plant oils are a major part of "green" cosmetic formulations, at least in an artisanal scale. In the industrial scale, the big and small names mainly use hydrocarbons and ester oils for an improved oxidation stability and increased shelf-life and use just enough plant oils to be able to have the tempting name of plant oils on their labels. When we start creating a new formulation we have a huge number of plant oils at our disposal. The oils and butters that were considered "exotic" a decade ago are easily accessible these days but just because we can access some exotic oils with sexy and tempting names is not enough to go create a formulation based on that plant oil.

Download our free guide for plant oils:

When it comes to emulsion making you need to consider the following factors:

- is this a cold process or a hot process emulsion

- the impact of the oil on the color of the emulsion

- the impact of the oil on the scent of the emulsion

- the oxidative and thermal stability of the oil

Basically the more of the "less stable" and "more susceptible" oils you use the shorter the shelf-life of your product. Apart from that although varying the oil (we are talking about triglycerides and not the hydrocarbons or ester oils) has a huge impact on the skin feel and sensory properties of the emulsion, there is little impact on the viscosity or physical stability of the emulsion.

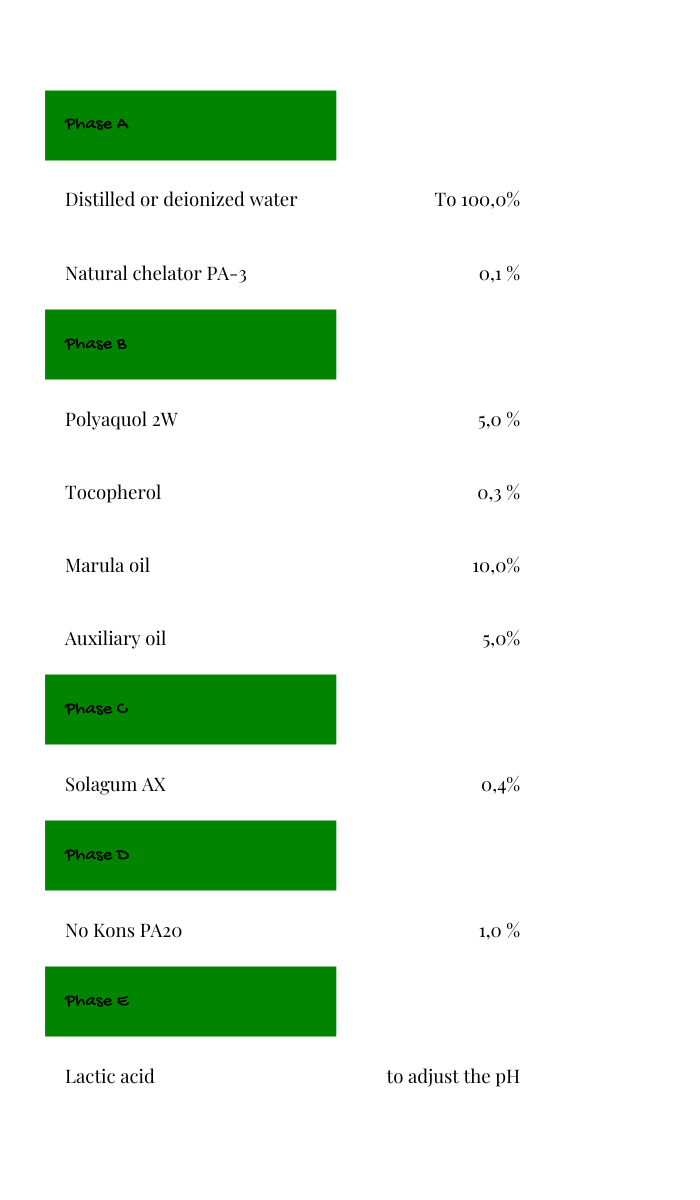

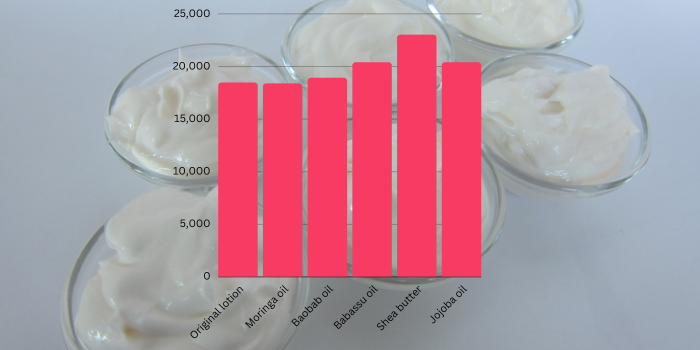

For this experiment we took one of our basic formulations from the previous tutorial and swapped 5% of the marula oil with other oils. Since we are making a hot process emulsion we only chose oils with a low iodine value/high thermal and oxidative stability. Swapping the oil has almost no significant impact even on the viscosity of the emulsion. Even by swapping the liquid marula oil with the babassu oil which is solid in winter the difference in viscosity is very insignificant. The only slightly difference in viscosity (which is not even significant visually) is by using jojoba oil which is chemically an ester and not a triglyceride and by using shea butter which is even solid or semi solid in summer.

This is the frame formulation we used in which we have used 15% total oil and used 10% marula oil + 5% of an auxiliary oil.

Visually you can hardly distinguish any huge difference in the appearance whereas the measurement reveals just a small increase in the viscosity by using shea butter as a part of the oil content.

Conclusion:

Selecting the oil for an emulsion (apart from considering the formulation concept and the therapeutic properties of the oil) mainly depends on the impact of the oil on the color and scent as well as the oxidative and thermal stability of the oil.

The more highly unsaturated oils you use the shorter the shelf-life of the emulsion. These oils are (specially in a hot process) usually used as an additive and not as the main part of the oil phase.

For most emulsifier: By swapping the triglycerides, there is a difference in skin feel and sensory properties of the emulsion but the impact on the viscosity and physical stability is non-significant. However oils with a high content of unsaponifiables and lecithin may still have an impact on the emulsion stability.

In the next part we are going to study the impact of fatty alcohols and waxes on the emulsion.