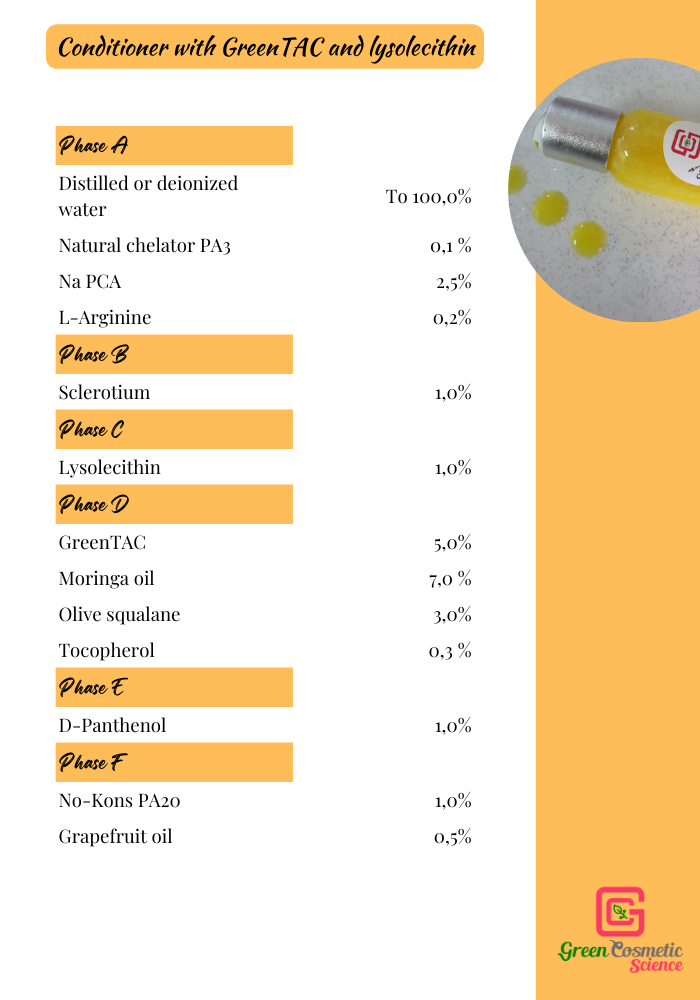

This beautiful conditioner which looks like liquid sunshine is the epitome of simple hair care. It is made with our amazing green conditioner base

and the lysolecithin to add a lecithin touch to the hair.

Don't feel intimidated by the number of different phases. The procedure is really simple

Procedure:

1- Blend phase A in a heat proof container. As we made this formulation for the first time the pH was 4,1 and we added some L-Arginine to increase the pH. Adding arginine to the water phase is much easier than adding it at the end to the finished formulation so that for the next batches we add the arginine from the beginning to the water phase. You can do the same for the first time you make this formulation and then add the amount of arginine you need for the consequent batches.

If you are still struggling with pH measurement and adjustment we have an ebook for you which is the juice and extract of our discontinued online course:

2- Heat phase A between 45-50 C and disperse the gum. Continue stirring for 45 minutes while the gum fully hydrates. Meanwhile blend phase D in another heatproof vessel.

3- Add the lysolecithin when the gum is hydrated

Get our free guide for gum dispersion here

4- Heat the water phase (consisting of A+B+C) and the oil phase @60 C

5- Emulsify the oil phase in the water phase and start cooling down while stirring

6- At a temperature <45 C add phase E and F.

7- When the conditioner reaches RT prepare a 10% dilution, measure the pH and adjust it if necessary. The preservative system we are using here works independent of the pH but we aim to keep the pH between 4,5-4,9. If you are working with another preservative system consider its pH dependence.

8- Take your microbial and stability samples and fill the rest in suitable containers