Natural gums are added to emulsions to enhance the stability (short term and long term), improve the texture and skin feel and make the emulsion suitable for the specific purpose, application and packaging.

There are 1001 ways to incorporate gums in an emulsion and there are tens of possible gums available to the formulator. Which gum or gum blend you use and which method you choose will depend on:

- the overall formulation

- the desired texture and viscosity range

- formulation procedure

- instruments and vessels

- the emulsifier system

just to name a few factors. There is no absolute "right" or "wrong" or any "one size fits all" solution but there is always a "best" solution for a certain application.

To show you a live example of the impact of the gum dispersion in an emulsion we created a KISS formulation (really KISS) and tried different gum incorporation methods. Actually we tried different gum blends and a lot more incorporation methods but we are only sharing the results for a single gum (Solagum AX which is a proprietary gum blend) and 3 incorporation method. The complete project will be published in a separate ebook in the coming months. The aim of this experiment and blog post is to inspire you to try different methods in your formulations and see which one gives you the better results. You will not know as long as you have not tried. It is possible that you get different results when you use another gum or another emulsifier but this is again something that you need to test in your system. Just be brave and test different methods and combinations and study the short term and long term results to find out the way and the blend that works for you the best.

This is our base formulation (the one you see in the video)

| Phase A | Dosage |

|---|---|

| Distilled or deionized water | to 100,0% |

| Aquaxyl | 3,0% |

| Chelator PA3 | 0,1% |

| Na-citrate | 0,5% |

| Phase B | |

| Solagum AX | 0,4% |

| Glycerine | 3,0% |

| Phase C | |

| Natural emulsifier GSC POF | 5,0% |

| Moringa oil | 20,0% |

| Tocopherol | 0,3% |

| Phase D | |

| D-panthenol | 1,0% |

| Phase E | |

| No-Kons PA20 | 1,0% |

| Cedarwood oil | 1,0% |

| Lactic acid | to adjust the pH |

Procedure:

1- Blend phase A and C in separate heat-proof beakers

2- Heat phase A and C in a water bath between 82-85 C

3- Emulsify the oil phase in the water phase

4- Disperse the gum+glycerine blend in the still hot emulsion

5- Start cooling down while still stirring

6- When the temperature reaches under 50 C add the sensitive phases (Phase D). We are using the natural D-Panthenol and it will loose its biological activity when it is heated above 70 C. This is why we add it during the cool down

7- When the emulsion reaches <35 C add the preservative system and the essential oils. The preservative system works independent of the pH

8- When the emulsion reaches the room temperature prepare a 10% dilution and measure the pH. In our case it was 6,88.

9- Reduce the pH by adding lactic acid. If you are making this formulation for the first time add the lactic acid gradually and measure the pH in between.

10- Prepare another dilution of the emulsion and measure the pH. In our case it was 5,20. We are aiming for a pH between 4,9-5,5.

11- Take the stability and micro kit samples and fill the rest in a suitable container

The result

This emulsifier creates medium viscosity emulsions specifically when all of your lipid phase is a liquid oil. We prepared tow other versions of the same formulation (in the video we show you the end results and not how to make them).

1- Blended the gum+ glycerine and dispersed and hydrated the blend in the cold water phase before heating the water and oil phase

2- Added the glycerine to the cold water phase and the gum to the cold oil phase before heating the oil and water phase. This is a method that most artisanal and novice formulators follow because they don't have any high shear mixer or homogenizer. Adding the gum to the oil phase avoids building lumps which is the nightmare of every formulator.

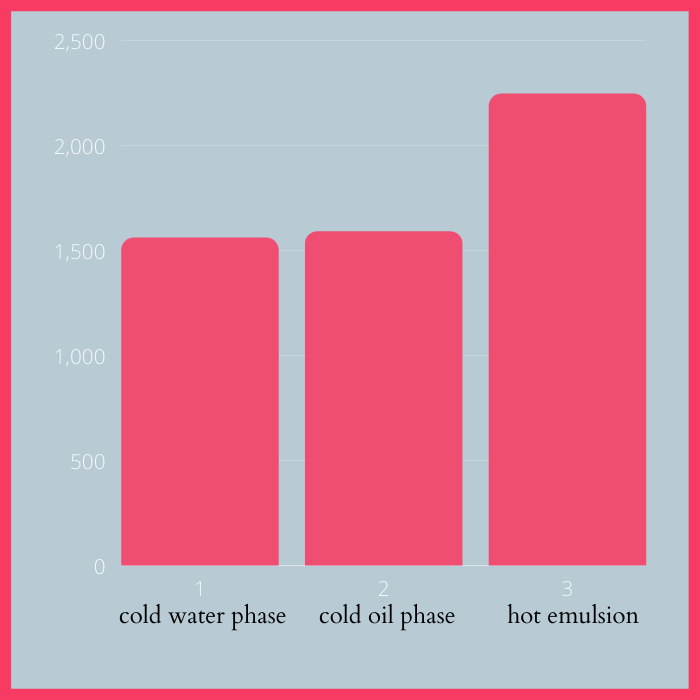

Here are the viscosity results:

All methods lead to stable emulsions. The first and second method create emulsions with a very similar viscosity but when you blend the gum in the oil phase the emulsion has some soapiness and does not absorb as fast into the skin as when the gum is dispersed in the water phase or in the hot emulsion. (This is not a universal rule. It is possible that you take another emulsion or another gum system and get different results)

The highest viscosity and the nicest texture is achieved when we dispersed the gum+glycerine blend directly in the still hot emulsion right after homogenization.

The homogenization is a little bit more tricky when you are working with a low-viscosity water phase (no gums in it) but you need to start at a low speed and gradually increase the speed as the emulsion is built and the viscosity increases.

Let us know which method of gum dispersion you use and whether you have ever tried different gum dispersion methods.

You can watch the video here