With the increasing popularity of botanical and plant based personal care the diversity and availability of the plant extracts is increasing as well. Once being considered as a luxury and being sparingly used by the mainstream just for the sake of the name of a fanciful extract on the label of the product, they are now indispensable not only in artisanal and natural formulations but even in mainstream products.

From aubergine to ziziphus, you can find commercial sources of plant extracts preserved or unpreserved in various carriers and solvents. Most Artisanal formulators and herbalist/formulators however prefer to create their own extracts mostly because they have access to high quality local herbs and while the extraction is a part of the magic. Nothing is more indulging than the view of high quality plants sitting in jars and glasses, releasing their goodness gradually into a carrier.

This is where the mystery begins: Which carrier?

If you want anything more than just a name on the label and want to have some real benefits and properties from your plant extracts then the first question you need to ask is: Which solvent shall I use for extraction?

Commercial plant extracts are available in a variety of hydrophilic and lipophilic extracts. Alcoholic and hydroalcoholic extracts are not often available commercially not because they are useless but because of all the safety and legal hassles of transporting large amounts of alcohol. So hydroalcoholic extracts are usually made in situ.

Hydrophilic extracts are usually made in blends of water and glycerine (hydroglyceric) or water and glycols (hydroglycolic). All of these solvents have different polarities and can solubilize or extract different types of molecules. This means the components of a hydroglyceric extract will be different to the components of a hydroglycolic or a hydroalcoholic extract. This is not the same with lipophilic extracts. The main solvents/carriers used for lipophilic extracts are sunflower, soy bean and rapeseed oil. All of them easily available at relatively high volumes and low price. Another type of lipophilic extracts is made by supercritical fluid extraction (most often CO2) in which the solvent is then separated from the extract and the extract remains without any carrier. Depending on the pressure/temperature conditions used for extraction CO2 extracts contain a variety of lipophilic components. They are usually much more expensive compared to the conventional lipophilic extracts or the related oils but have a much longer shelf-life and a much clearer profile in terms of the composition,

When you decide to make your own extracts, you need to choose the carrier or solvent based on the active ingredients you plan to get out of the plant. Obviously most plants have both lipophilic and hydrophilic phytochemicals and you certainly can not collect all of them by using one solvent. You either need to be selective and go for either hydrophilic or hydrophobic extract or combine both types of extracts for hydrophilic and lipophilic phytochemicals. The type of extract depends as well in the formulation you are going to create. With emulsions it is rather easy because you have both a water phase and an oil phase and can apply both hydrophilic and hydrophobic extracts in the formulation but with single phase formulations such as toners or balms you need to stick to one type of extract.

If you have any experience or knowledge in botanic and herbalism you certainly know that the quality and the composition of the extract will depend on many other factors such as the soil, the harvest time, the parts of the plant used for extraction and even the climatic conditions within a certain species. Usually the phytochemicals are not sitting on top of the leaves and petals, They are hidden inside certain cells and in order to get to them you will need a combination of mechanical, thermal and osmotic forces to break the cells and release the goodness out of them.

As an example and in this post I am sharing the results of a very interesting study in which they have measured and compared the total polyphenol content of a few plants using different methods and solvents. This is one of the few scientific articles dedicated to this extremely important and popular topic but I am sure the research is ongoing in this field and we will observe more useful quantitative measurements being published in the near future.

This is a very interesting article (look at the reference) but for those of you who have no patience to go through a detailed and long article I will summarize some results.

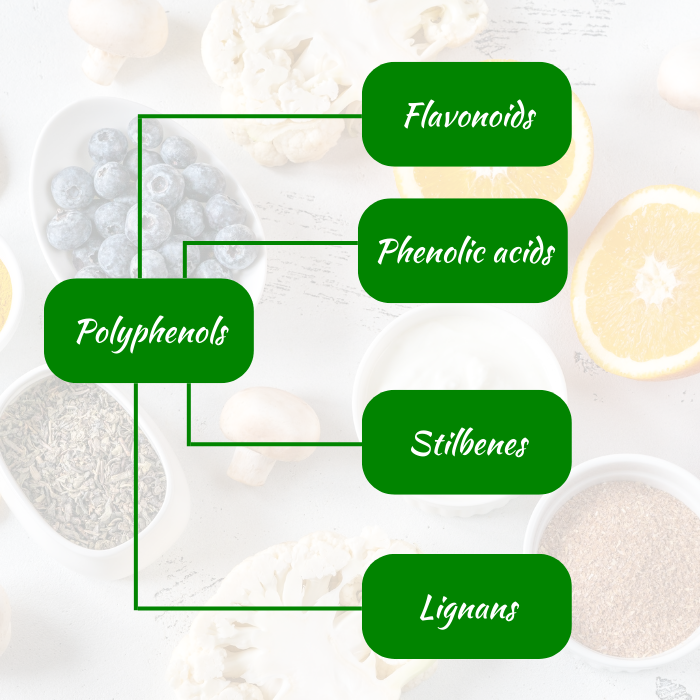

Polyphenols are a group of secondary plant metabolites that are available in every parts of the plants such as roots, stems, fruits and flowers. We have written a series of posts about the phytochemicals a long time ago. You can refer to this one for polyphenols

Polyphenols are among the most widely and intensively studied plant metabolites. Over 8000 polyphenols are so far discovered. These molecules which owe their name to phenol, a highly carcinogenic aromatic chemical mainly protect the plants against UV radiation, bacterial and fungal infections as well as against herbivores. They are gaining popularity in modern medicine, pharmacy, food and nutritional supplement industries as well as in cosmetics.

The colour of elderberry and raspberry, hibiscus petals and many other plants and fruits is mainly composed of polyphenols. These are molecules that change their form and colour with pH.

Polyphenols are mostly antioxidant and hence are using both in dietary supplements and in cosmetics as anti-oxidants, rejuvenation ingredients and UV absorbers. In the article I am referring to in this post they have measured the total polyphenol content, the SUI parameter (which is an expression of UVA absorption), the SPF and a couple of other characteristics of the plant extracts. The results are quite fascinating.

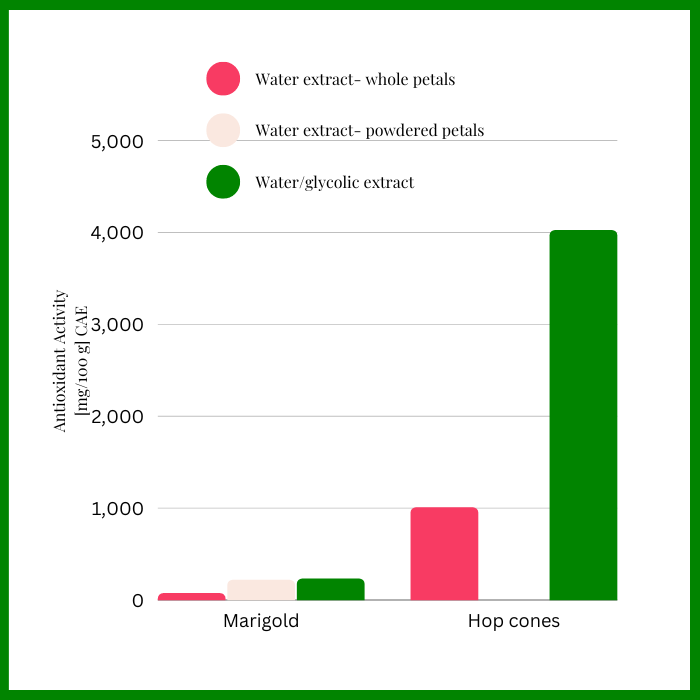

The difference in antioxidant activity is quite obvious. For marigold, when the petals are crushed and extracted with water the results are similar to whole petals extracted with a blend of water and glycol. In both cases the results are much higher than when water alone is used to extract the whole petals. For hop cones the different between water alone and water-glycol as the solvent is even more remarkable.

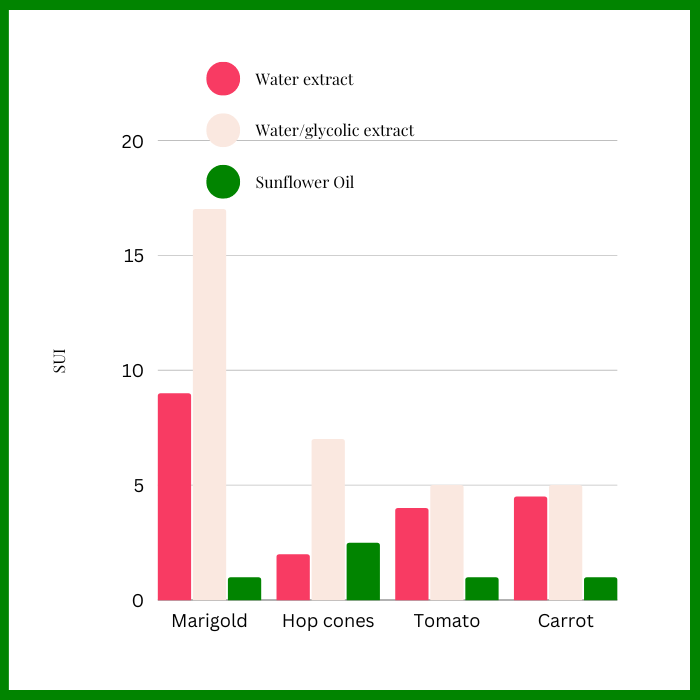

SUI (Spectral Uniformity Index) Parameter is an assessment of the radiation protection against UVA. Look at the results for calendula, hop cons, tomato and carrot extracts as a factor of the solvent

The bottom line:

No matter if you decide to make your own extracts or purchase them ready made. Be aware that not only the solvent but even the method of extraction and the plant parts will have a qualitative and quantitative impact on the phytochemicals in the extract. If you are extracting your plants for anything more than just the name of the extract on the label, first define which properties you expect from your extract. Then make a literature survey to find out which chemicals contribute to those properties and then go search for literature about a quantitative measurement of those components in similar studies like here or do some research about the polarity of the components you are looking for to figure out which solvents/solvent blends to choose.

Reference:

Kurzawa, Marzanna, et al. "Total Phenolic Content, Antioxidant Capacity and UV Radiation Protection Properties of Marigold (Calendula officinalis), Carrot (Daucus carota), Tomato (Solanum lycopersicum) and Hop (Humulus lupulus) Extracts." Cosmetics 9.6 (2022): 134.