Natural gums are used in oil in water emulsions to increase the viscosity of the water phase and to improve the stability of the emulsion.

Depending on the gum nature, the instruments you have available and the batch size and type of the formulation you may choose one method or other for incorporating the gum in the formulation. Here there is no absolute right or wrong but there is always a method that gives you the best outcome.

We have already made some experiments with gums and different methods of dispersion and since we still have questions and comments coming to us we dedicated another set of experiments to this subject.

You can read our previous posts before you proceed:

The impact of gum dispersion on the emulsion

Gum dispersion 101

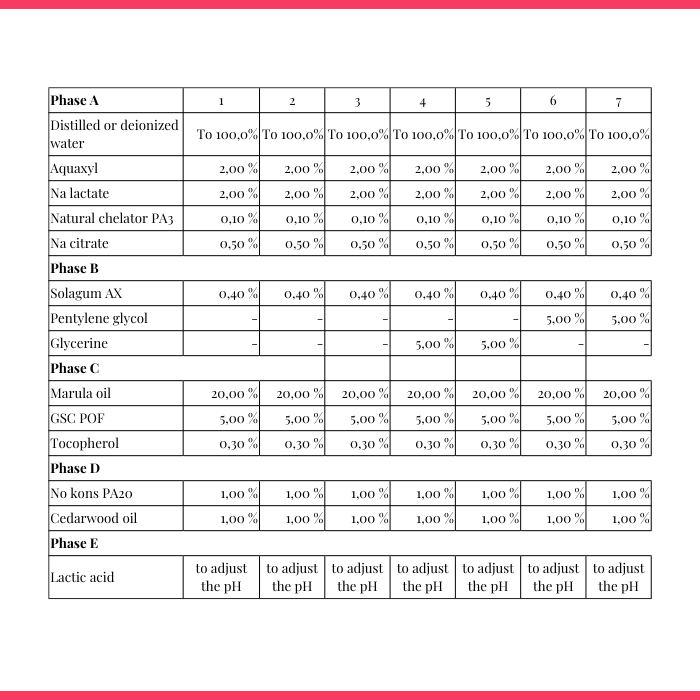

For this post, we took a similar approach and made a KISS emulsion with Glyceryl stearate citrate which is a humble and easy to work anionic emulsifier. We used only Slagum AX which is a proprietary blend of xanthan gum and acacia gum. Both of these gums are fully hydrated @RT and don't necessarily need heat for hydration.

This is our base formulation

For the first 3 samples we only used the Solagum AX without any solvent.

1- Solagum AX dispersed in the hot emulsion after homogenization

2- Solagum AX dispersed in the cold water phase before heating the water phase

3- Solagum AX was added to the oil phase before heating the oil phase

In the next 4 samples we prepare a slurry of the gum + a solvent. This method is very often used in the food and pharmaceutical industry as well as by home crafters and artisanal manufacturers. Making a slurry makes the dispersion easier and reduces the risk of building limps which are then very hard to break.

We used two samples with glycerine and two samples with the plant based pentylene glycol.

4- Solagum AX+ 5,0% glycerine dispersed in the hot emulsion

5- Solagum AX+ 5,0% glycerine dispersed in the cold water phase before homogenization

6- Solagum AX+ 5,0% PG dispersed in the cold water phase before homogenization

7- Solagum AX+ 5,0% PG dispersed in the hot emulsion after homogenization

The above diagram shows the samples as well as the viscosities. All samples are stable and they look very similar. The difference in the viscosity is hardly recognizable by just observing them. The glycerine samples are slightly tacky and have a slightly inferior glide compared to the samples with PG or without any solvent at all.

We got the highest viscosity by dispersing the gum (without any solvent/slurry) in the hot emulsion. The next highest viscosity was by blending the gum and PG and then adding this blend to the emulsion. Both PG and glycerine reduce the viscosity slightly compared to the first/original sample. Using PG has teh advantage that it is a preservative booster.

So what?

As mentioned before, there is no wrong or right here. Which method you choose depends on your instruments and your formulation. I suggest you use 2-3 of these methods in a formulation and then compare the results and see which one works better for you, creates a smoother emulsion or helps you spare time and energy.

We came to the conclusion that in our lab and when working with emulsifiers that create medium to high viscosity emulsions, adding the gum directly to the hot emulsion creates the best results for us and helps us spare time. This will not be the case when we use other gums or use a cold process emulsifier.

Stay safe and unstoppable