Vitamin C is one of the sexiest ingredient right now but creating a stable product that works is a challenge. We have been working on hydrogel serums over the past years and tested the stability in and out. We have shared several formulations in our member's area and today we are going to share the formulation for this beautiful serum with you.

The formulation is not exactly KISS but it is rather simple. We are using amigum which is sclerotium gum and can easily stabilize low concentration of lipophilic ingredients without the need for any emulsifier.

Since we are using a preserved hydrosol with a low pH we add some arginine at the beginning to increase the pH. Then we measure the pH before adding the preservative since the stability and the efficacy of our preservative depend on the pH. After adding the preservative we remeasure the pH and adjust it to make sure it is in the efficacy range. If we were using distilled water or a hydrosol with a higher pH we wouldn't have added any arginine at the beginning.

If you are confused and overwhelmed by all this increasing and deacreasing of pH adjustment and don't know what to do and when to measure the pH, check our flagship course that is totally dedicated to the business of measuring and adjusting the pH in cosmetic formulations

You can check our previous video/blog tutorial with the tutorial for a hydrogel serum with ceramide NP here

Barriere protective hydrogel serum

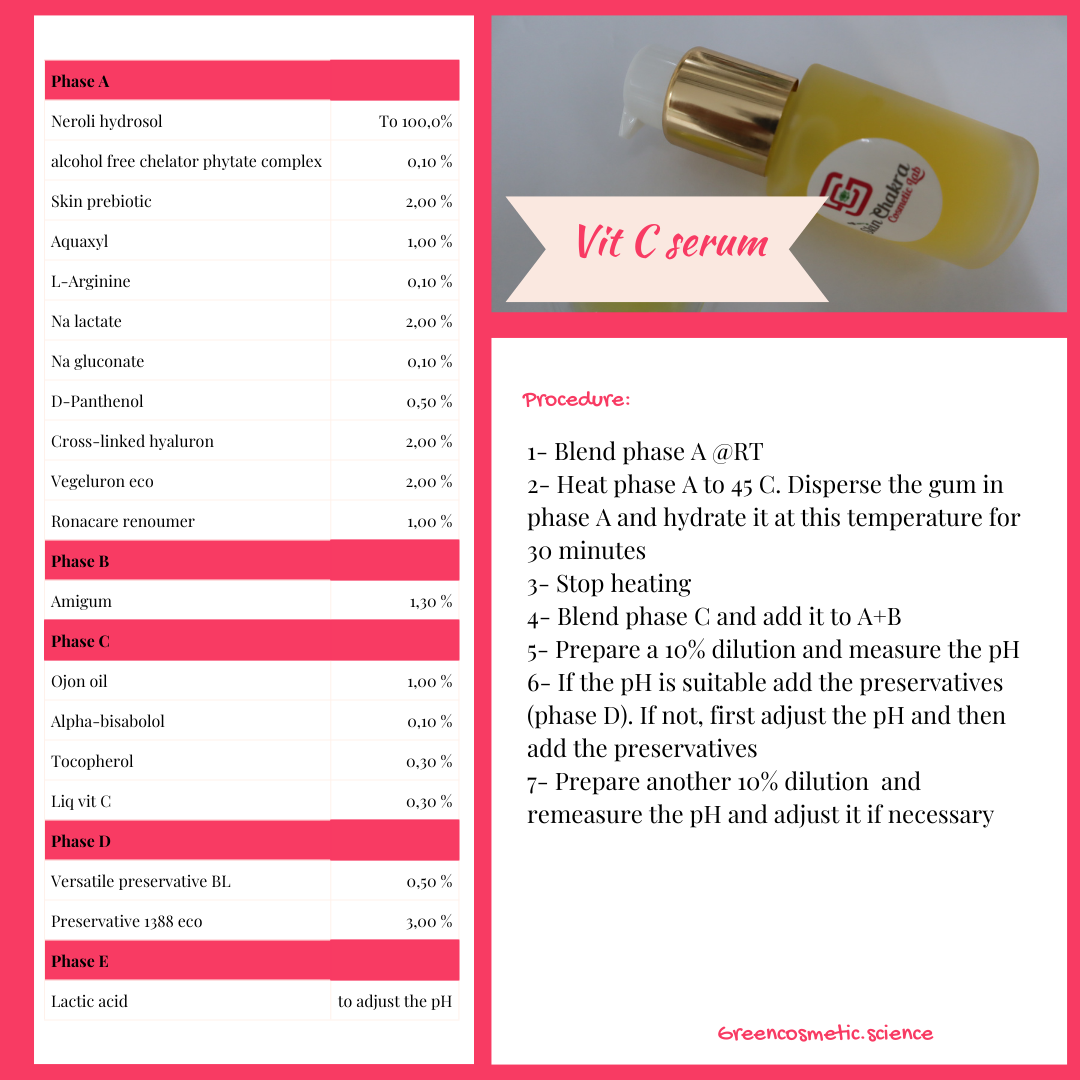

Here we go for this formulation:

Procedure:

1- Blend phase A @RT

2- Heat phase A to 45 C. Disperse the gum in phase A and hydrate it at this temperature for 30 minutes

3- Stop heating

4- Blend phase C and add it to A+B

5- Prepare a 10% dilution and measure the pH

6- If the pH is suitable add the preservatives (phase D). If not, first adjust the pH and then add the preservatives. In our case it was 5,15 and since we know that this blend increases the pH we added the preservative without any further adjustment (this is why we added the arginine at the beginning)

7- Prepare another 10% dilution and remeasure the pH and adjust it if necessary. In our case it was 5,54 which is slightly higher than the efficacy and stability range of the preservative (5,2-5,5) and we reduced the pH by adding lactic acid to 5,4.