If you belong to my generation you have perhaps a chronic apathy against W/O emulsions. I have this apathy since I started using those heavy, sticky sun protection creams that were more suitable as an insect trap than a skin care product. This apathy remained with me till I started formulating W/O emulsions for a customer. That changed my whole perspective towards W/O emulsions.

The skin feel of the W/O emulsion, just like any other emulsion mainly depends on the nature of the emulsifier and the choice of the oils you are using.

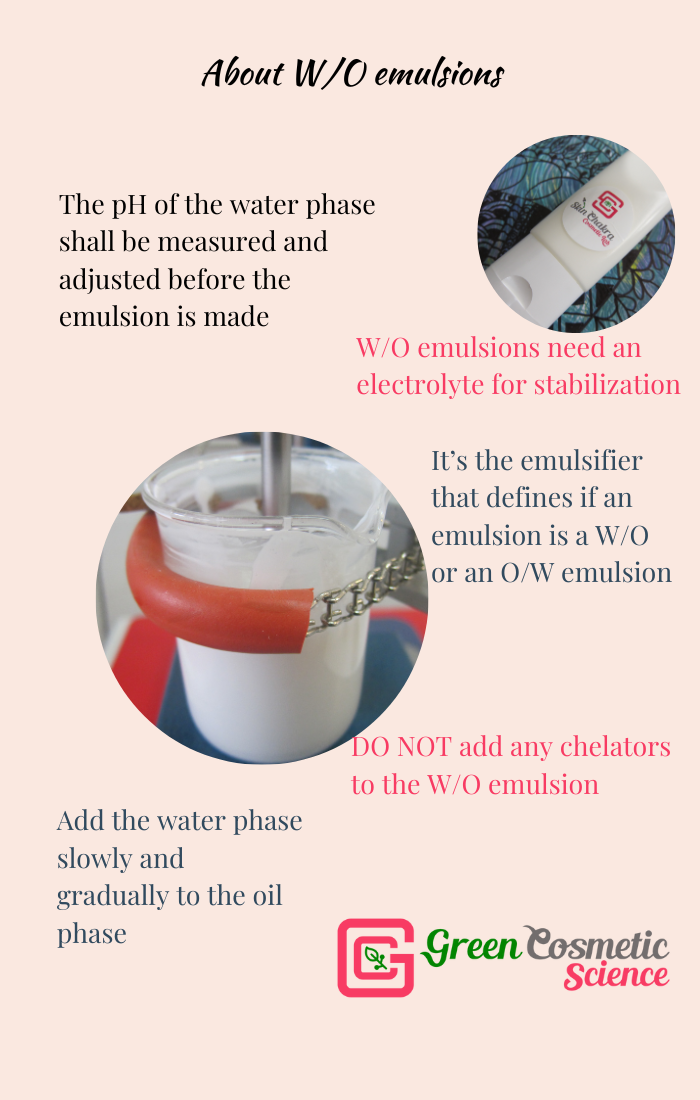

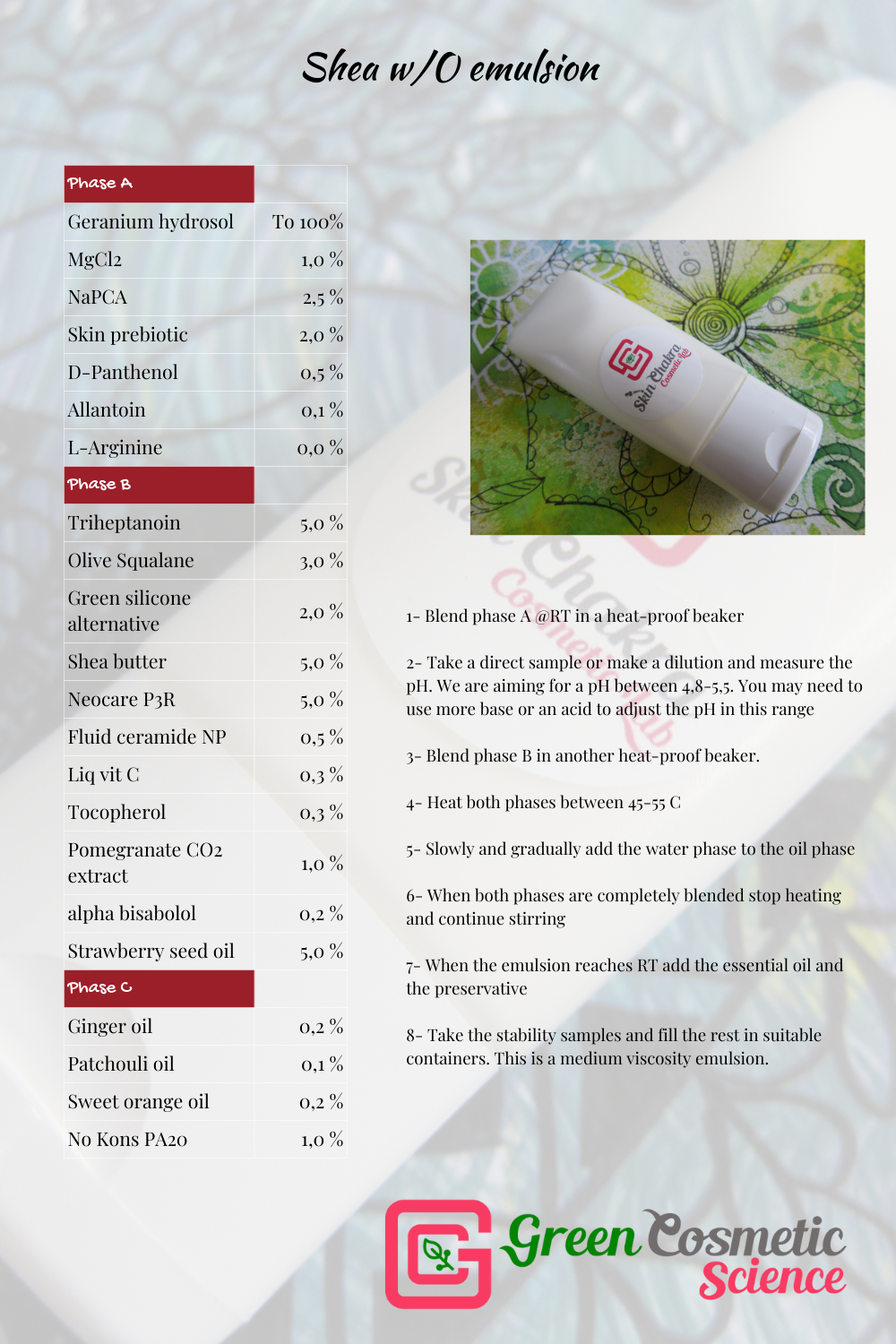

For this formulation we are using the Neocare P3R which is a proprietary blend of Polyglyceryl-3 Polyricinoleate and Polyglyceryl-3 Ricinoleate. This is a cold process emulsifier that you can as well use in a hot process (like every other cold process emulsifier). We have discussed the advantages and disadvantages of cold and hot process in this webinar a while ago and have used the Neocare P3R to show the difference in an example and you can go back and watch the webinar by clicking on the photo or the link above.

For this specific formulation and to get ready for the cold season we are using shea butter and hence we can not proceed through the cold process. However we do not need to go through a hot process as well. We are using our fluid ceramide here that needs to be incorporated at a temperature above 45C. If we aren't using the ceramide we would go with a warm process and heat both phase between 40-50 C. With the fluid ceramide we need to go slightly higher so we heated the phased between 45-55 C.

We have created a slightly different emulsion last year and you can go and read the tutorial and watch the video before coming back to this formulation.

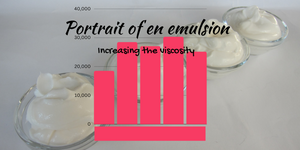

This formulation is not quite KISS in terms of the number of ingredients but believ me every single ingredient (specially the lipids) are chosen to improve the stability, skin feel and viscosity of the emulsion. As you see, we are using different classes of lipids with different polarities. You can simplify the formulation and use just one plant oil as the whole oil (+ the shea butter of course) but that will affect the stability, texture and skin feel of the formulation.

If you are still struggling with the oil polarity concept we have a replay of our masterclass which is available here

Once again to our choice of oils. The strawberry seed oil may seem a weird oil for a product for winter care but despite its juicy, summary name, this oil has an amazing fatty acid profile that makes it super suitable for barrier protection purposes. This is why we are using it but again, feel free to replace it with any other liquid oil. Since this is not a "hot" but a "warm" process we add almost all of the ingredients together and you can see that we have conveniently added the D-Panthenol and the skin prebiotic in the water phase from the beginning.

One other factor that you need to take care of is the pH measurement and adjustment. As you know, you need to measure and adjust the pH of W/O emulsions before the emulsion is made. This can sometimes become annoying specially when you are working on a new formulation. This is why we recommend making your first samples in small batches.

We have a pH measurement and adjustment blueprint file that is the juice of our pH measurement course for those who want a quick fix and do not want to go through the whole course. This file includes flowcharts for every possible product type that you can imagine. Going through different possibilities for each product category such as: starting with a hydrosol or with distilled water, working with a preservative that works dependent of the pH or independent.

.png)

Anyway, enough of talking about the emulsion. Let's jump to the formulation and procedure.

Procedure:

1- Blend phase A @RT in a heat-proof beaker

2- Take a direct sample or make a dilution and measure the pH. We are aiming for a pH between 4,8-5,5. You may need to use more base or an acid to adjust the pH in this range

3- Blend phase B in another heat-proof beaker.

4- Heat both phases between 45-55 C

5- Slowly and gradually add the water phase to teh oil phase

6- When both phases are completely blended stop heating and continue stirring

7- When the emulsion reaches RT add the essential oil and the preservative

8- Take the stability samples and fill the rest in suitable containers. This is a medium viscosity emulsion.

Watch our introductory video about W/O emulsions here