I can not help singing the praise of the lotion bars.

I have mentioned this a zillion times and am going to repeat it again: these are the products to start with if you are an artisanal formulator with a limited budget.

Even the big industry has now realized that waterless products are a key solution to improve the climate disaster we have brought upon ourselves during the last 200 years. Despite some of my colleagues I don't believe we can go completely waterless and I still enjoy the application of a toner or a lotion over my skin but I personally try to avoid water containing formulations as often as it is possible and so is the environmental conscious population around the world.

So let's wrap up the benefits of making lotion bars

- Making lotion bars is one of the easiest tasks in the cosmetic lab. You really don't need a huge investment in machinery and instruments and can start with no budget at all

- You don't need to go through the hassle of pH adjustment and measurement

- You don't need to fumble around viscosity adjustment

- The products are self-preserving. Although you need to have a meticulous GMP, you don't need to go through the hassle of microbial and challenge testing and although I am not a fan of "free from" claims, you can claim preservative free for the lotion bars as long as this claim is still legal in your country

- The stability testing for lotion bars is easy and straightforward

- You are not shipping 80%+ water as you ship the product, the consumer is not paying for 80%+ water and the environmental impact is hugely different compared to shipping a water containing lotion

- You need just a couple of formulations to create endless varieties of shapes and colors, seasonal products or evergreen products

- The packaging is much less complicated and you can pack these beauties completely plastic free. They are used till the latest milligram. No need for collecting the jars and bottles from your customers, paying for the packaging recycling or offering a refill in order to reduce waste.

There are still a lot of advantages but I don't want to keep you longer from making these beauties for the Easter so I'll jump to the formulation...

This section of the industry is THE ONE SECTION where the artisanal and small manufacturers are a head and shoulder above the big industry. I am not recommending you never create and sell awesome creams and lotions. I am just telling you that instead of trying to compete against the huge marketing campaigns of the bog boys with all their bells and whistles and celebrity and influencer endorsements, start making and selling these easy going products and build your community and loyal customer pool and then expand to more fanciful formulations if you want.

Before we proceed you may want to have a look at these previous formulations:

Now let's jump to the formulation

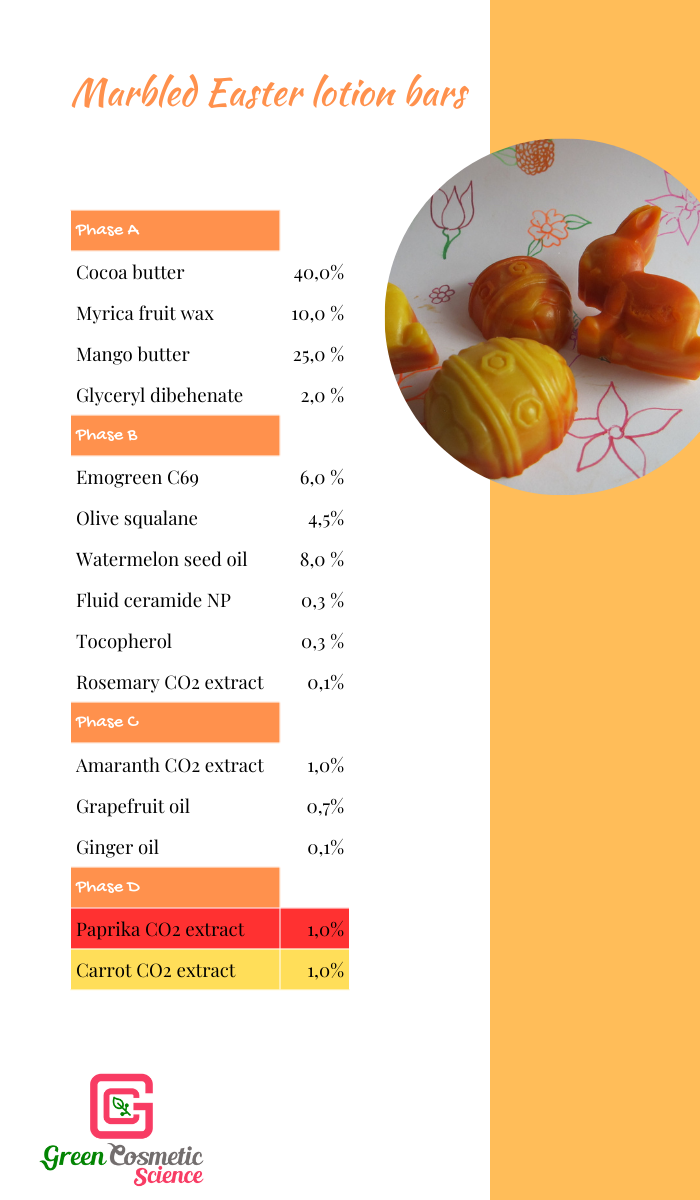

You can make these bars mono-color and that's the easy version of making the bars. This time we wanted to create a marbled effect to make the product optically more appealing. That is a little bit more complicated when it comes to pouring the batter in the mold cavities. For the first couple of times call a buddy to help you till you get the hang of it. The outcome is really worth the extra step.

Procedure:

1- Melt phase A in a water bath between 80-85 C until G2b is completely melted.

2- Blend phase B in another beaker

3- When phase A is completely melted stop heating and add phase B

4- Stir while cooling till the temperature reaches <35 C.

5- Add phase C

6- Divide the batter in 2 (eyeballing is absolutely enough) and then add the carrot extract in one part and the paprika extract in the other part.

7- Pour the batter alternatively in the mold cavities to create this marbled effect. As an alternative you can marble the batters in your beaker and then pour the blend in the mold cavities (if you are a soap maker you know how it works)

8- Put the molds in the fridge between a few hours to overnight (depending on the size of the cavities)

9- Demold the pieces and wrap then in tissue paper